Woodworking Jigs You Can Not Live Without

Woodworking jigs are indispensable tools that enhance precision, safety, and efficiency in the workshop. They serve as specialized guides or fixtures, enabling woodworkers to perform repetitive tasks with consistent accuracy. Whether you’re a novice or a seasoned craftsman, incorporating essential jigs into your workflow can significantly elevate the quality of your projects. Below, we explore some must-have jigs that every woodworker should consider:

- Crosscut Sled

A crosscut sled is an invaluable accessory for making precise crosscuts on a table saw. It provides a stable platform that holds the workpiece securely, minimizing the risk of kickback and ensuring clean, accurate cuts. This jig is particularly useful for cutting wide or long boards where a standard miter gauge might fall short. Building a crosscut sled is a straightforward project that pays dividends in improved safety and precision.

- Dado Jig

Cutting accurate dadoes and grooves is essential for strong joinery in cabinetry and shelving. A dado jig, typically used with a router, allows you to cut straight, even channels that fit your mating pieces perfectly. Some designs are adjustable, accommodating various widths to match different material thicknesses. Investing time in creating a reliable dado jig can streamline your joinery process and enhance the structural integrity of your projects.

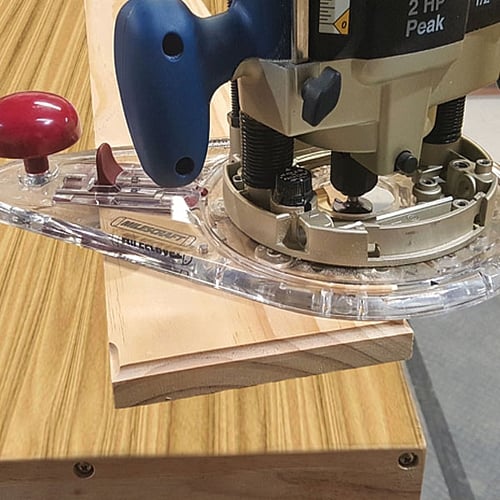

- Router Circle-Cutting Jig

When your project requires perfect circles or arcs, a router circle-cutting jig becomes indispensable. This jig attaches to your router and allows you to cut circles of varying diameters with ease and precision. Whether you’re crafting round tabletops, decorative inlays, or speaker cutouts, this jig ensures uniform results every time.

- Tapering Jig

A tapering jig is essential for creating angled cuts, such as those needed for table legs or decorative elements. It allows you to cut consistent tapers safely on a table saw, ensuring that each piece matches perfectly. This jig enhances both the aesthetic appeal and structural integrity of your tapered components.

- Box Joint Jig

Box joints are a strong and visually appealing option for constructing boxes, drawers, and casework. A box joint jig enables you to cut evenly spaced, interlocking fingers that fit together snugly. This jig can be used with a table saw or router, providing versatility in your joinery techniques. Mastering the use of a box joint jig opens up new possibilities for creating durable and attractive joints.

- Featherboard

Featherboards are safety jigs that apply consistent pressure to hold your workpiece against the fence or table surface during cutting operations. They help prevent kickback and ensure cleaner cuts by stabilizing the material. Featherboards are versatile and can be used with table saws, routers, and bandsaws, making them a staple in any woodworking shop.

- Tenoning Jig

For crafting precise tenons, a tenoning jig is invaluable. This jig holds the workpiece vertically and guides it through the blade, ensuring accurate and repeatable cuts. A well-designed tenoning jig enhances the strength and fit of mortise-and-tenon joints, which are foundational in traditional woodworking.

Incorporating these jigs into your woodworking arsenal not only improves the quality and precision of your work but also enhances safety and efficiency. While some jigs can be purchased, building your own tailored to your specific needs can be a rewarding endeavor that further hones your skills. As you expand your collection of jigs, you’ll find that many complex tasks become more manageable, allowing you to tackle more ambitious projects with confidence.

Comments

Add comment