Why You Need An Air Filtration System

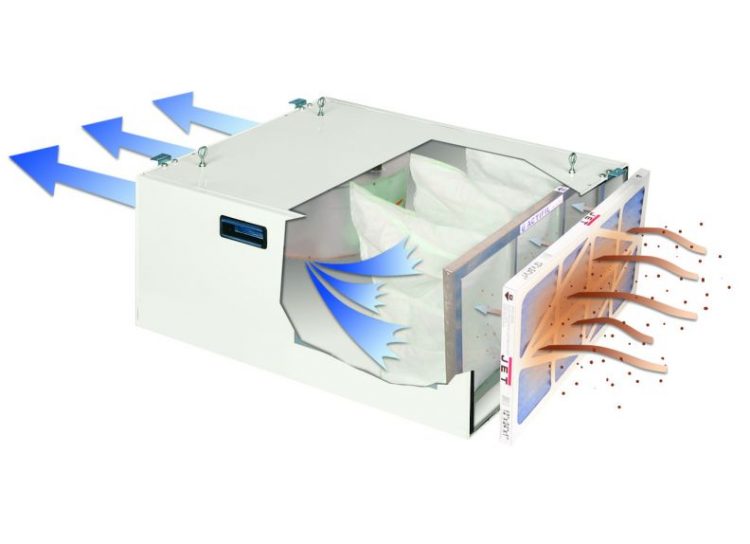

When cutting or sanding wood, it is impossible not to generate dust. It is the annoying aspect of woodworking, the mosquito at the picnic. This is where an air-filtration system comes into play. This machine, which is typically suspended from the ceiling, draws dust-laden air through one or two filters before exhausting (hopefully) clean air out the back. A common shop hack was also included: an R500 box fan with an R300 furnace filter. The outcomes may surprise you.

Utilize an air-filtration system as a supplement to a dust collector and shop vacuum, which collect debris directly from the machines and tools causing the mess. Do not rely on one of these devices as your primary dust collection system. Before these machines can filter the air, they must initially draw in air. A lot of it. The smallest visible dust particles are approximately 10 microns in diameter. (Human hair typically ranges in diameter from 40 to 60 microns.) Particles smaller than 10 micrometers can remain suspended in the air for at least 30 minutes, making them suitable for inhalation.

All that airflow is meaningless if the unit does not capture airborne particles.

Maintaining These Air Filters

All rectangular-box machines are equipped with both a prefilter and a secondary pocket filter. Each is easily accessible for maintenance. The Minimum Efficiency Reporting Value (MERV) rating is used to classify furnace filters. The greater the number (between 1 and 16), the more effective the filter is. Filters for woodworking machinery may not always specify a MERV rating, but they will typically indicate the smallest particle size, in microns, that they can effectively trap.

The inner high-efficiency filter is made up of large “pockets” of dense fabric designed to trap particles that pass through the prefilter. You can also clean these with compressed air; before cleaning, read the owner’s manual. Because replacements for these filters are 4-5 times the price of prefilters, keep the prefilter clean or replace it frequently to preserve the inner filter.

When vacuuming a filter, ensure that the filter traps the fine dust you remove rather than simply returning it to the shop air. If your vacuum can’t handle it, or if you’re using compressed air, clean the filter outside where dust can escape into the open air.

As dust particles accumulate on the filters, airflow decreases while filtration improves. As a result, you’ll need to strike a balance between adequate airflow and filtration. We recommend cleaning the prefilter every 7-10 days of working in the shop to be on the safe side.

More Dust Extraction Solutions From Toolmate

Comments

Add comment