Unlocking Precision: A Guide to Sharpening Forstner Bits

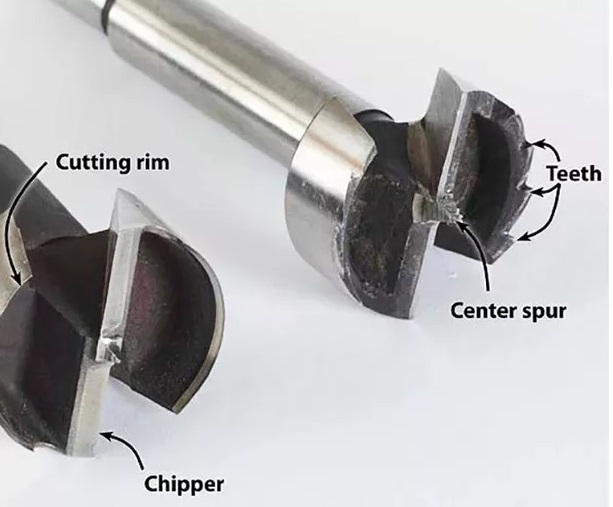

Forstner bits are indispensable tools in woodworking, renowned for their ability to create clean, precise holes with flat bottoms. However, like any cutting tool, Forstner bits require regular sharpening to maintain their cutting efficiency and precision. In this comprehensive guide, we’ll delve into the importance of sharpening Forstner bits and provide step-by-step instructions for achieving optimal sharpness.

Forstner bits are indispensable tools in woodworking, renowned for their ability to create clean, precise holes with flat bottoms. However, like any cutting tool, Forstner bits require regular sharpening to maintain their cutting efficiency and precision. In this comprehensive guide, we’ll delve into the importance of sharpening Forstner bits and provide step-by-step instructions for achieving optimal sharpness.

Understanding the Importance of Sharp Forstner Bits:

Sharp Forstner bits are essential for achieving clean, accurate holes in wood. Dull bits can cause tear-out, chipping, and rough edges, compromising the quality of your woodworking projects. By keeping Forstner bits sharp, woodworkers can produce smooth, precise holes with minimal effort, resulting in professional-quality finishes.

Assessing Bit Sharpness:

Before sharpening Forstner bits, it’s essential to assess their current sharpness. Inspect the cutting edges for signs of wear, dullness, or damage. Dull bits may exhibit chipped edges, visible wear patterns, or a loss of cutting effectiveness. By identifying areas in need of sharpening, woodworkers can target their efforts effectively and restore the bit’s cutting performance.

- Secure the Bit: Begin by securely clamping the Forstner bit in a vise or holding fixture to prevent movement during sharpening. Ensure the bit is held firmly and stable to maintain control throughout the sharpening process.

- Preparation: Clean the cutting edges of the Forstner bit using a wire brush or abrasive pad to remove any debris or residue. This step ensures that the sharpening process focuses on the cutting surfaces without interference from buildup or contamination.

- Select the Sharpening Method: Forstner bits can be sharpened using various methods, including hand sharpening with files or stones, powered sharpening systems, or dedicated Forstner bit sharpeners. Choose the method that best suits your preferences and available equipment.

- Sharpening the Cutting Edges: Carefully sharpen each cutting edge of the Forstner bit using the selected sharpening method. Maintain a consistent angle and motion to achieve uniform sharpening across the entire cutting surface. Take your time and focus on restoring the original cutting geometry to ensure optimal performance.

- Honing and Polishing: After sharpening, hone the cutting edges using a fine-grit sharpening stone or honing compound to remove any burrs or rough edges. Polish the cutting surfaces to a mirror-like finish for enhanced cutting efficiency and longevity.

- Final Inspection: Once sharpening is complete, inspect the Forstner bit for sharpness and smoothness. Test the bit on scrap wood to verify its cutting performance and ensure it produces clean, precise holes with minimal effort.

By following these steps and dedicating time to sharpening Forstner bits regularly, woodworkers can maintain peak cutting performance and achieve exceptional results in their woodworking projects. Sharpening Forstner bits is a fundamental aspect of tool maintenance that enhances efficiency, precision, and overall woodworking satisfaction.

Comments

Add comment