Sharpening By Hand – The Basics

As woodworkers, much of our work is dependant on a sharp and reliable cutting edge. For our surfaces to be truly flat, for our cabinets to precisely fitting, and for our logs to be smooth and perfectly cylindrical – we need sharp tools. For those who can afford it, machine Waterstone sharpeners like those made by Tormek have been an irreplaceable tool in the workshop. More revered, sometimes, than the most celebrated planer/thicknesser. In this article, we explore the various honing guides available in the market as well as briefly go over the number of stones available for purchase. These are also explored further in our previous article Sharpening Stones Quick Start Guide.

Stanley 0-16-050 Sharpening System

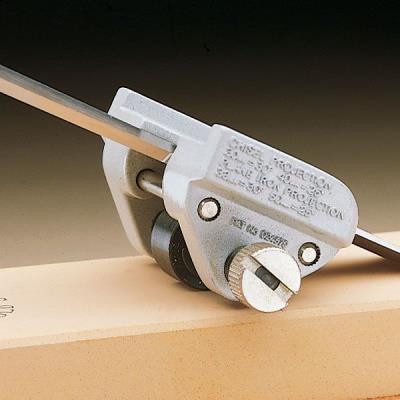

Introduced by Stanley Works, this honing guide can be found in almost every woodshop which has existed since its inception. Very simple and elementary in its design, the Stanley Honing Guide features a slot in which the user inserts the blade of their chisel or plane and from then on the operate can tightly clamp the blade in the guide’s “vice”.

The Stanley Honing Guide has two thumbscrews on either side which are used to clamp the blade onto the guide. To set the guide to the required angle, the honing guide comes with a suggested distance that the blade must protrude from the edge of the guide to raise the blade at an angle.

What is the correct angle?

For a standard bench and butt chisel, the desired angle for general woodwork would be 25°. These tools are usually ground to this angle straight out of the factory. However to obtain an angle that lasts longer and is more ideal for fine woodwork, woodworkers have for decades suggested that the user adds 5° micro-bevel – bringing the cutting edge to a 30° angle.

The WoodRiver Honing guide is a fine example of the more modern and improved version of the Honing Guide which was introduced by Stanley Works. This honing guide greatly improves on the Stanley 0-16-050 by simply adding two features that made life a lot easier and made your sharpening stones last longer as well.

The WoodRiver Honing Guide has a blade clamp much like that found on the Stanley guide however, unlike the Stanley version, the user only adjusts one large thumbscrew to tighten and set the blade to the desired angle. This reduces the chance of having your blade sharpened skew. One adjusts the screw without needing to “eye-ball” whether the blade is indeed straight.

This is the most premium honing guide kit currently available on the market. It features a strongly built high-quality blade clamp that squares and sets the blade in one step. The Veritas Honing Guide also features a larger camber roller which is wider than the average roller found on the Stanley and the WoodRiver honing guides. This decreases the chance of developing craters on your stones. This set also includes a measuring scale which the operator can easily use to set the required angle for the blade.

Sharpening Stones

One has a variety of stones to choose from. The most common of these is the traditional oil stones that use oil to be lubricated. These have been used in the west for centuries whereas the Japanese have always preferred the Natural Waterstones. These stones are known to create a sharper edge but are also very prone to wearing away. The strongest and most reliable of these stones are the Diamond Stones. These offer a cleaner workspace (as they require very little lubrication) and stay flat for years. Read more about these in our previous article Sharpening Stones Quick Start Guide.

Comments

Add comment