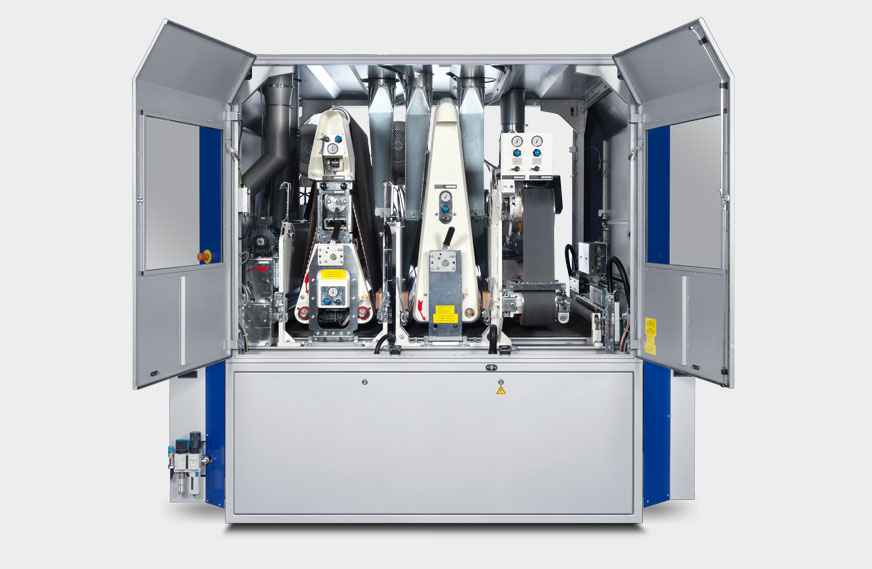

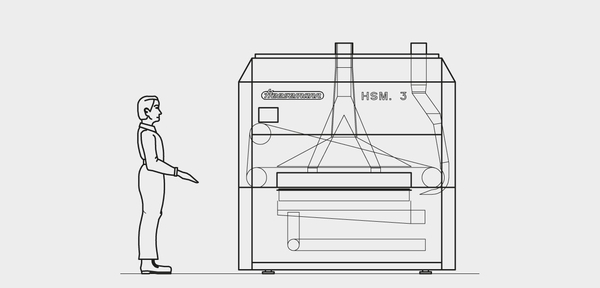

HSM .2/.3

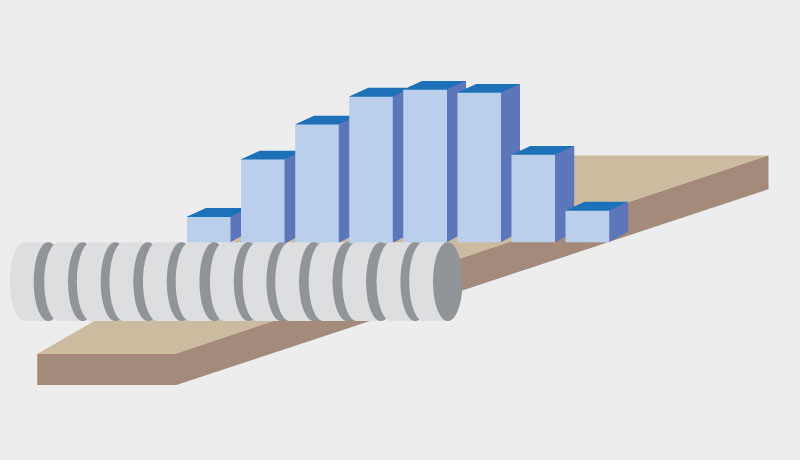

Heesemann HSM is the accurately fitting surface sanding machine for the needs of small and medium-sized craftsmen and industrial companies. Be it effect sanding, cross sanding, lacquer or high gloss sanding, be it boards, solid wood or veneered work pieces – Heesemann HSM is the sanding machine for craftsmen! The surface sanding machine is particularly suitable for carpenters for instance. The currently very popular sanding effect “Vintage Look” can be achieved with a special sanding program.

The Heesemann HSM is available in predefined standard configurations, equipped with two or three sanding units and can be equipped with a cross sanding to utilize the cross sanding method.

Thanks to its standardized set-up, the HSM offers proven Heesemann sanding technology like the integrated CSD® magnetic pressure beam with an outstanding price-performance ratio. The Heesemann HSM is the perfect sanding machine to enter the premium segment of sanding.